The addition of magnetic stripes requires special attention. Our application method ensures a standardized position. Our sophisticated equipment allows for targeted and consistent positioning, an important process that minimizes rejection during encoding and guarantees proper functioning at the point of sale.

Stripe characteristics:

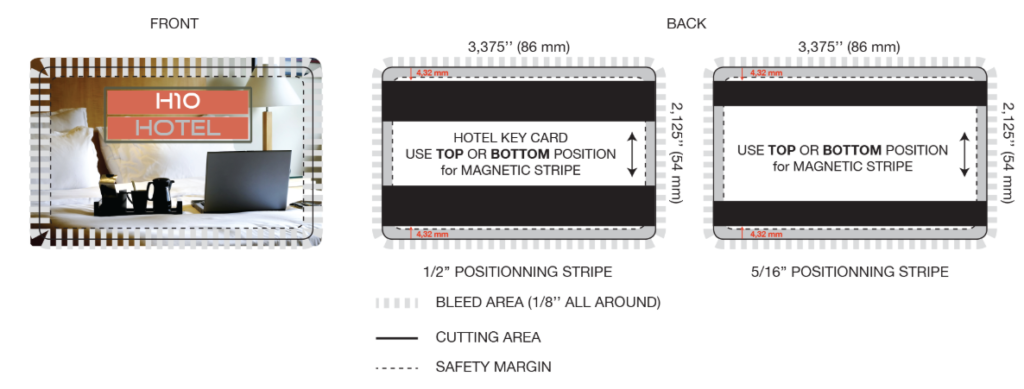

Stripe width: 5/16” (8.4mm) and 1/2” (12.7mm)

Encoding on 2 tracks (or up to 3 tracks for a width of 1/2”)

Coercivity level: HiCo (2750oe) LoCo (300oe)

GRAPHIC CHARACTERISTICS:

To create a graphic layout that meets the technical specifications required for production, please follow these guidelines to optimize the process and the manufacturing time of plastic cards.

Final card format:

CR 80, 3.375″ X 2.125″ ( 86 mm X 54 mm )

Printing:

- 4/4 (color on front / color on back)

- 4/1 (color on front / black on back)

- 4/0 (color on front only)

Bleed:

Allow for an additional 1/8″ (3.2 mm) of bleed around the card in the final format in order to prevent white from showing once cut.

Text:

Allow for a safety margin equal to 1/8″ (3.2 mm) inside the card.

Types of files accepted:

- AI Illustrator CS6 (curvy fonts & embedded images)

- InDesign CS6 (fonts & images in a compressed file)

- High resolution PDF

Back:

See images above to check the AREA OF APPLICATION OF THE MAGNETIC STRIPES ON THE BACK

Quality of the black :

It is best to use a very rich black (C: 65% – M: 65% – Y: 65% – K:100%), to optimize the opacity of the black. This procedure is recommended for solids covering a large area.

Text may remain in black only.